When you are labeling soap, one of the problems you run into is figuring out the net weight to put on the label. Since water will continue to evaporate out of the soap over time, the soap will gradually come to weigh less, even after the initial “cure time.” When the consumer is deciding whether to purchase the product, the net weight stated on the label MAY NOT be more than the actual weight of the product.

There are a couple of ways to ensure that the net weight stated on the label is less than (or equal to) the actual weight of the soap bar.

Factors to Consider

When selecting a method to calculate your final net weight to print on your label, take into consideration these factors:

How long will it be between the time your soap is packaged and the time it is sold? The shorter the time between packaging and selling, the less change (from evaporation) there will be in the weight.

Do you know the environment in which it will be stored between packaging and sale? Will it be in a consistent temperature and humidity? When the environment is stable it is much easier to predict how it will affect the soap.

Second, what environment will the soap be in after it is packaged? If you know that your packaged soap will always be in your shop in a controlled environment, then you can predict the rate of water evaporation (continued drying) over time. If you sell wholesale and the soap will be in a store, or if there are temperature and/or humidity changes where you store the soap, then it is much harder to predict what the drying rate will be.

Soap is sold immediately

If the soap is to be sold immediately (within a few days) of when it is packaged and labeled with the weight, the net weight is unlikely to change significantly. To be on the safe side, you might want to round down a bit (just to cover possible changes during the day, especially if you are outside or in the sun).

Stored in a stable environment

If you will be storing the finished soap in a predictable and stable environment, you can calculate the drying rate over time. This method takes a little more time to set up because you have to measure the weights over time and determine the weight loss. After you’ve made the calculations once, you can use them over and over to calculate the future weight of your soap.

How to Calculate the Weight Loss Percentage

Yes, it’s math(!), but it’s not too hard if you just take it step by step.

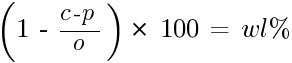

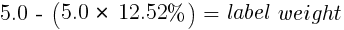

First, the basic formula:

Where: is defined as the current weight

is defined as the current weight is defined as the packaging weight

is defined as the packaging weight is defined as the original weight

is defined as the original weight is defined as the weight loss

is defined as the weight loss

How to use the formula

Here’s an example of the step-by-step process to use the formula. Of course, you’ll need to use your actual numbers for your own soap.

Step One

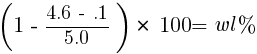

The first step is to plug in the numbers = current weight =

= current weight =  oz

oz = packaging weight =

= packaging weight =  oz

oz = original weight =

= original weight =  oz

oz

Step Two

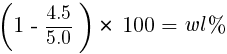

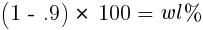

Then do the calculations, one at a time:

A.

B.

C.

D.

Weight loss to that point in time is 10%.

Calculating Changes Over Time

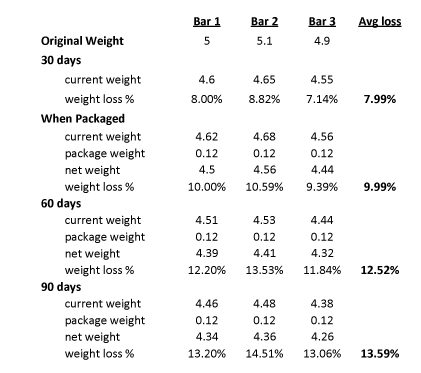

In order to predict what the the weight of your soap will be in 30, 60, 90 or more days, you need to make the calculations over time (and keep records).

Step by Step

- Immediately after you unmold and trim a batch of soap, select several (2-4) bars to be your “test weight” bars. Record the weight of each and then dry (cure) them as usual, with the rest of the bars in the batch.

- After 30 days (or one month), weigh each test bar again. Record the weight and calculate the percentage of weight loss for each bar using the formula above.

- Calculate the average weight loss (add the weight loss of all the bars and then divide by the number of bars).

- When you are ready to package the soap, weigh each test bar again (before packaging). Record the number of days, individual weight loss and average weight loss.

- Package the test bars in the same way you package the other bars in the batch, and weigh them again. Record the weight each time. The weight of the packaged soap less the weight of the unpackaged soap gives you the weight of the packaging. Keeping track of the time and weight of the packaging is important because it will probably affect the rate of weight loss.

- After 60 days (or 2 months) from the original weighing date, weigh the test bars again. Record the weight LESS the weight of the packaging. Calculate the percentage of weight lost for each bar, and the average between all bars.

- Record the weight and calculate the percentage of weight lost of the test bars every month until all the bars from the batch are used or sold.

- If it might be 90 or more days before your soap is sold, continue to weigh the test bars every 30 days (1 month) for as long as they might be held before being sold.

At the end, you should have a chart that looks something like this:

What to put on the label

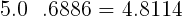

Once you know the percentage of weight loss over time, you can figure out what to put on the label using this formula:

If the soap will sell in not more than 60 days, then take the weight of the bar when first cut and trimmed (the original weight) and multiply it by the average weight loss in 60 days and deduct that from the total. If it will be sold in 90 days, use the weight loss for 90 days.

Example: Using the chart above, for a soap being sold in 60 days:

Round down, and put 4.8 oz net weight on the label.

Different Soaps, Different Calculations

If you make soaps with different formulations–particularly if they have different percentages of water or have bulk additives (such as oatmeal or herbs), they will have different drying rates. You’ll need to do the calculations for each type of soap individually.

The good news is that, provided the formulation and environment don’t change much, you can continue to use your calculations over and over again.

In Part 2

In part 2 of this series, we’ll discuss how to calculate the final weight of the soap based on the soap formulation itself, without having to worry about taking measurements over time.

Leave a Reply