Tracking your ingredients (through specifications, vetting suppliers, ordering, receiving, inspecting, and using) is a core component of good manufacturing practices (GMP). It’s one of those “behind the scenes” systems that ensures your products are safe, consistent, and compliant—even if you’re a small-batch maker working out of your home studio.

Let’s dig into what’s expected and how you can put it into practice within your own workflow.

Why Tracking Matters

When you know exactly what ingredients you have, where they came from, and where they went, you can:

- Prove product safety and traceability if there’s ever a question about a batch.

- Ensure consistency—the same ingredients used the same way make the same great product.

- Meet MoCRA’s GMP expectations, which include documentation of ingredient handling and recordkeeping.

- Catch problems early—an ingredient that looks off or arrives damaged can be flagged before it goes into production.

Regardless of the size of your operation, this kind of tracking shows you take your business seriously.

Step 1: Specifications—Know What You’re Buying

Each ingredient you use should have a specification sheet (often called a spec sheet or technical data sheet) describing what it is and what makes it acceptable for your use.

It might include details like:

- Product name

- Product description

- Chemical or accepted name (for botanicals, the Latin name is important)

- Purity or concentration

- Appearance and odor

- Any specific requirements (such as particle size, melting point, etc.)

Keep your specification sheets on file: they’re your baseline. When something arrives, you can compare what you got to what you expected.

PRO TIP: When you’re setting up your ingredient specification sheet, get a Certificate of Analysis from your supplier for the ingredient you know is correct, and use that as a basis for your spec sheet.

Step 2: Choose Sources That Can Meet Your Specs

Once you know what you need (your specifications), the next step is deciding who you’re willing to buy it from.

For each ingredient, identify one or more suppliers that can reliably provide a product that meets your specs, and keep a record of:

- Supplier name and contact info

- Their product name and item number

- Your preferred package size(s)

- Price per unit or per pound/kilo

- Any certifications or documentation (COSMOS, organic, IFRA certificate, allergen statement, etc.)

This step gives you a vetted list of acceptable sources for each ingredient.

Why it matters:

- If one supplier is out of stock, you already know who else carries an acceptable version of that ingredient.

- You’re less likely to grab “something close” in a pinch that doesn’t actually match your specification.

- You can compare prices and packaging options without starting from scratch every time.

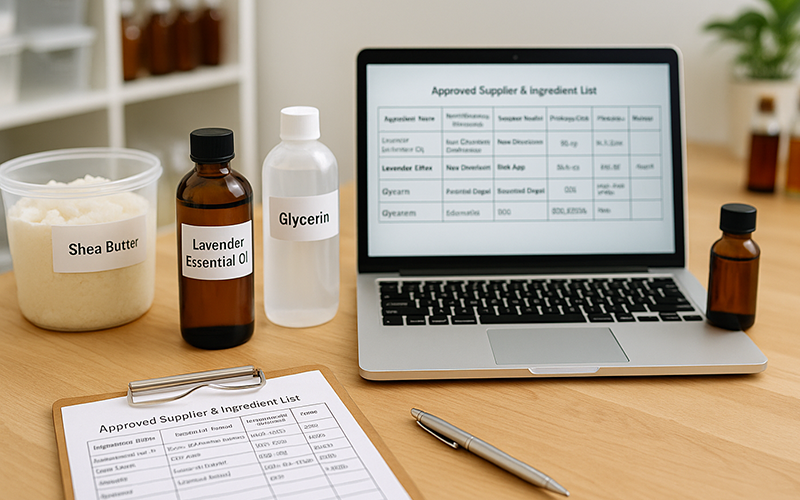

PRO TIP: Create a simple “Approved Supplier & Ingredient” list—one line per ingredient, with all acceptable suppliers and their item numbers. This becomes your go-to reference when reordering.

Step 3: Ordering—Keep a Record

When you place an order (with any of your vetted suppliers), make a note of:

- The supplier

- The date ordered

- The product/item number (their code for the ingredient)

- The lot number (if available at the time of order)

- The quantity and size

- The price and any shipping or handling fees

- The expected delivery date

Having this record helps you match what arrives to what you ordered—especially if you buy the same ingredient from more than one supplier.

Step 4: Receiving—Inspect on Arrival

When your ingredients arrive:

- Set the package aside until you can inspect and verify it. Do NOT add it into your regular stock without inspection and verification.

- Check the labels. Make sure the name, lot number, and supplier information are present and match your order.

- Inspect the packaging. Look for leaks, dents, broken seals, or signs of contamination.

- Verify the contents. Does it look, smell, and feel like it should, based on your specifications?

- Record the supplier’s lot number. If provided, record it so you can go back to the manufacturer with details if needed.

- Record the expiration date. If the product has an expiration date, record it.

- Attach the supplier’s Certificate of Analysis. If you didn’t get a copy with your order, download it from the supplier’s website or request a copy.)

- Assign an internal lot number. This is the lot number you can use to track your use of the ingredient.

- Record the date received and the condition of the ingredient.

If anything seems off, don’t use it, and don’t store it with your accepted ingredients. Set it aside until you’ve confirmed it’s okay. Contact your supplier immediately for clarification, replacement, or a credit.

When you have verified the ingredient, add it to your normal inventory.

PRO TIP: Write the date received, expiration date, and your internal lot number right on the container label with a permanent marker or sticker. It’s simple and keeps things clear later.

You can attach the inspection form to the order form and invoice to create a permanent record. Scan and file electronically, or keep a paper file, filed by supplier or by date of order.

PRO TIP: Keep a log of each ingredient ordered and received that lists: ingredient name, date ordered, supplier, price, received date, your internal lot number, expiration date, and storage location.

Step 5: Storing—Keep It Safe and Organized

Proper storage extends ingredient life and maintains quality:

- Keep oils and butters cool and out of sunlight.

- Store essential oils and fragrances tightly sealed, in dark bottles, in a cool environment (or even refrigerated).

- Keep powders and dry ingredients tightly closed and away from humidity.

- Make sure every container clearly shows ingredient name, supplier, your internal lot number, date received, and expiration date.

A good storage system means you can find what you need and you’ll know which lots are oldest (so you can use those first).

Step 6: Using—Log Each Batch

Every time you make a batch, your batch record should have a place to record:

- The internal lot number for each ingredient used.

- The quantity of each ingredient you actually used.

- The batch number assigned to the batch.

That way, if there’s ever a problem—say, a supplier recalls a raw material or you discover an issue with a particular lot—you can trace exactly which finished products were affected.

For more information on keeping the batch records, see Good Manufacturing Practices: What’s the Point?

Putting It All Together in Your Workflow

You don’t need fancy software to do any of this. Start with what fits your current workflow:

- Notebook or binder: Log specifications, suppliers, orders, and batches by hand.

- Spreadsheets: Use Excel or Google Sheets with separate tabs for ingredients, suppliers, orders, and batches.

- Digital systems: If you’re using production or inventory software, look for features to track lots and supplier info.

The key is consistency—every ingredient, every time, from specification all the way through to use.

The Big Picture

Ingredient tracking isn’t just about compliance. It’s about professionalism and confidence.

When you can trace your products from raw materials to finished jars, you show your customers—and yourself—that your business is built on care and responsibility. If something ever goes wrong, you’ll have the information you need to respond quickly and appropriately.

It’s one of the simplest ways to make sure that what you’re making today is just as good (and just as safe) as what you made yesterday, and what you will make tomorrow.

Leave a Reply