Sometimes the net contents of each product in a batch can vary a little bit — it’s just a fact of life, especially with handcrafted products. Let’s examine what that means in terms of labeling your product.

The Regulations

The regulations say the net quantity of contents must be an “accurate statement of the quantity of contents of the package.”

However, there is a provision for:

- Reasonable variations caused by loss or gain of moisture during the course of good distribution practice or

- Unavoidable deviations in good manufacturing practice.

BUT, “variations from stated quantity of contents shall not be unreasonably large.“

Let’s unpack that in the real world.

Accurate Statement

The net contents (weight or volume) on the label must be accurate. You should weigh or measure carefully and accurately to determine the amount to put on the label.

You cannot modify the statement with qualifiying phrases, such as:

- when packed

- not less than

- average

Variations in the Net Contents

The regulations allow for reasonable variations due to gain or loss of moisture content during distribution. That is often the case with soap, which can lose weight over time due to moisture evaporation.

They also allow for unavoidable deviations in good manufacturing practices. That might occur when you have soap with a decorative top.

Calculating Allowed Variations

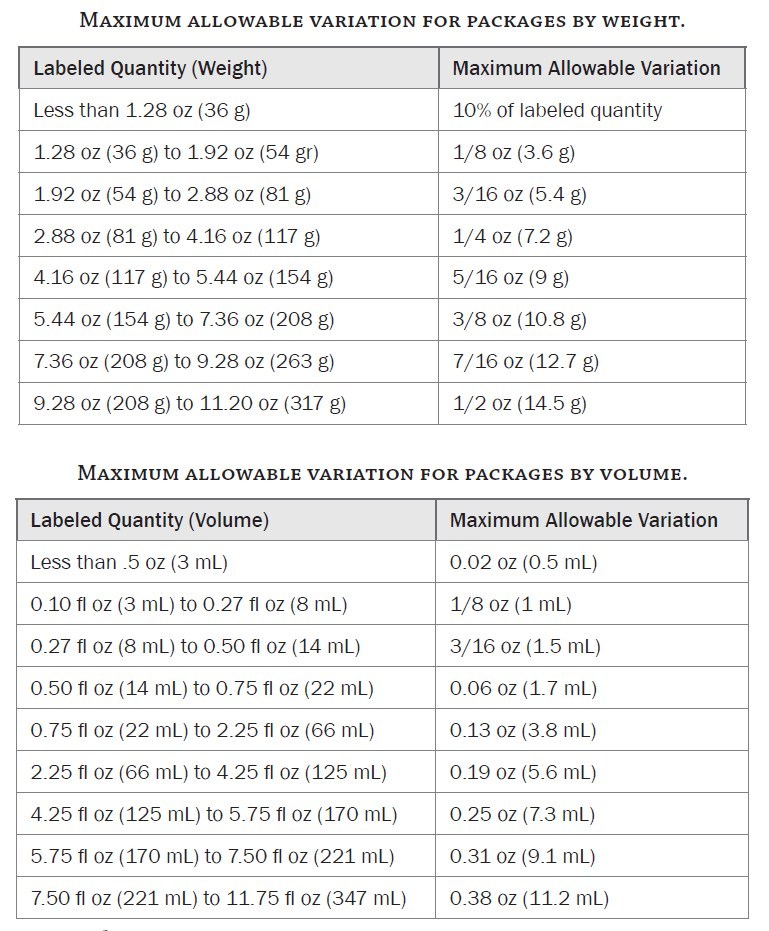

While “reasonable” isn’t directly defined in the regulations, the process for calculating the accuracy of net contents is outlined by the National Institute of Standards and Technology (NIST) in NIST Handbook 133, “Checking the Net Contents of Packaged Goods.”

There are two parts to testing accuracy,

- The average packages in the whole lot

- Negative errors in individual packages

If either check fails, then the whole batch fails.

Also, keep in mind that these checks may be WHEN PACKED (like if they were inspecting your facility), OR they could be checked AT RETAIL (as part of a general check on correct labeling).

1. Average Package Weight

The first requirement is based on the average net quantity of the packages in the lot. To calculate, the inspector takes all of the packages in the lot (or, if the lot is very large, a sampling of the packages), and calcuates the average for each package.

For example, if the lot is 25 bars of soap, each bar is weighed. The weight of all bars is added up and then divided by the number of bars (25) to get the average weight per bar,

1. The average weight must be equal to or greater than what is stated on the packages.

2. Negative Errors

The second requirement is that no single package may vary more than the allowed amount. The weight of each individual package that is LESS than the amount stated on the label is checked to verify it does not vary more than the allowed amount.

2. No single package may deviate more than allowed

Examples

Note: The following examples use 10 bars of soap; in reality, a larger sample would likely be used.

In these examples, the soaps are labeled as Net Weight 4 oz.

From the chart above, the allowed variation is 1/4 oz.

A 4 oz soap with the maximum allowed variation would be 3.75 oz.

Example 1

| Bar 1 | 4.0 oz |

| Bar 2 | 4.25 oz |

| Bar 3 | 3.9 oz |

| Bar 4 | 3.79 oz |

| Bar 5 | 4.1 oz |

| Bar 6 | 4.0 oz |

| Bar 7 | 3.86 oz |

| Bar 8 | 4.12 oz |

| Bar 9 | 4.0 oz |

| Bar 10 | 4.15 oz |

| Total | 40.17 oz |

| Average | 4.02 oz |

Average is more than 4 oz.

None have a negative variance of more than .25 oz

(all weigh more than 3.75 oz).

Batch PASSES

Example 2

| Bar 1 | 4.0 oz |

| Bar 2 | 4.25 oz |

| Bar 3 | 3.9 oz |

| Bar 4 | 3.72 oz |

| Bar 5 | 4.1 oz |

| Bar 6 | 4.0 oz |

| Bar 7 | 3.86 oz |

| Bar 8 | 4.12 oz |

| Bar 9 | 4.0 oz |

| Bar 10 | 4.15 oz |

| Total | 40.10 oz |

| Average | 4.01 oz |

- Average is more than 4 oz.

- One has a negative variance of more than .25 (weighs less than 3.75 oz).

Batch FAILS

Best Practice

Even though there is this little window that allows for negative variations in the net contents, best practice is to always calculate the net weight as the lowest amount it MIGHT be, and put that on the label. That accounts for any variations in your manufacturing process. For soap, take into account how much water loss there MIGHT be, and label accordingly.

That way, no matter when or where some inspector checks your net weight, you’ll never be overstating the weight (and therefore deceiving your customers about how much product they are actually getting).

Leave a Reply

You must be logged in to post a comment. Login/Register