Your label does more than identify your product and meet compliance requirements—it also tells a story. That story is not just what’s ON the label–it is also the label itself. The material, finish, ink, and even adhesive all contribute to how your product feels in the customer’s hands and how well it holds up in the real world.

In the world of paper and printing, just about anything is possible… for the right price. The truth is that specialty shapes, sizes, inks, and finishes can be prohibitively expensive and require quantities that are excessive for small makers.

In this article I’ll cover options that are available for small-batch makers and how to select the best stick-on label for the job.

Factors to Consider

There are several main factors to consider when figuring out your actual physical label:

- Ink

- Stock

- Size

- Adhesive

- Availability

The most challenging part is finding a physical label that meets your needs in all these respects. It can take some research to find something that works for you. Depending on how you approach it, you might look at the available stock, choose the size, ink, and adhesive, and then check if what you want is available. Or maybe you start by looking for the size you need, seeing what’s available, and then picking your stock, ink, and adhesive. Regardless of how you approach it, if you don’t ensure that all aspects meet your needs, you’re likely to encounter trouble down the road.

Ink

While ink may not be the sexiest decision point, it is often one of the most important because it’s dependent upon what printer(s) you have available to you. Generally, the options are laser or ink jet. There is also a special type of ink jet printer, a sublimation ink jet that infuses the ink into the stock, but it is limited to very specific stocks (generally polyester or polyester coated).

If you plan to purchase a new printer for printing labels, you have additional options, such as sublimation inkjet printers or models that print on labels on rolls. It’s a good idea to walk through the entire process of determining the best stock and other options for your labels, and then verify which printer(s) they actually work with, before making a final purchase.

Stock

The “stock” refers to the material for your label. The most common materials are paper, vinyl, and polyester, either as sheets or pre-cut labels on sheets. The stock can be self-adhesive or not, although in this article, we’re concentrating on self-adhesive labels.

There are two main considerations when selecting your preferred stock: the look and feel fits with your brand and image, and what sort of product it will be used on.

For example, if you have a very rustic brand, then a brown craft paper label might work for you, but if you are going for a high-end luxe image, brown craft paper is definitely not a fit. Similarly, if you have a shampoo to be used in the shower a paper label won’t work; you’d need a waterproof (or at least weatherproof) label.

Self-adhesive sheet labels are usually available in three primary stock types: paper, vinyl, and polyester.

Plain paper comes in a gazillion weights, colors, sizes, and textures as well as pre-printed with a gazillion different designs (such as those used for stationery or scrapbooking). However, paper adhesive labels are much more limited. Generally, basic paper labels come in white and some basic bright, neon, and pastel colors. Specialty papers or finishes are typically only available in white. Foil-coated papers in gold and silver (and occasionally other colors) may also be available.

Vinyl and polyester labels are weatherproof or waterproof (be sure to read the directions). They are trypically available only in white with either a matte or glossy finish.

Finally, many stocks come with coatings designed specifically for either a laser printer or an inkjet printer. Using the wrong type of printer for the stock can result in the print bleeding, running, fading, cracking, or peeling off. For best results, carefully read the specifications, get a small amount of the stock you think you want to use and then TEST, TEST, TEST with the printer(s) you have available to you. Sometimes an additional coating may be needed to ensure the ink doesn’t change or migrate over time or in different circumstances.

Size

The next thing to consider is the size you need–or at least your size options.

If you are printing the material yourself, you will likely need to get sheets (not rolls) and stay within the sizes that can be printed on a typical home printer: letter size (8 1/2 x 11 inches) or legal size (8 1/2 x 14 inches).

If you want pre-cut self-adhesive labels, you can either go with a “stock” size (that is, one that is stocked and available to purchase), or full-size labels are usually available, allowing you to cut them into custom sizes yourself. However, pre-cut labels tend to look more professional due to their rounded edges and precision cuts.

There are a LOT of stock sizes available, particularly when you purchase from a company that deals specifically with labels for soap and cosmetic handcrafters. General label companies may have nearly as many label sizes, and may be cheaper, but you’re likely to have to purchase 50 of 100 label sheets at a time.

Selecting the correct size

Of course, the size depends on what you are labeling. For many bottles and jars, you have the option of a single label that wraps all or most of the way around, or separate front and back labels.

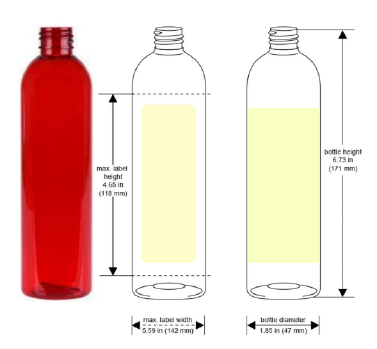

For example, an 8 oz cosmo bottle is about 6″ around and the height of the label-able area is about 4.5 inches. Therefore you could use a 6″ x 4″ label OR you could use two labels (front and back) that are 2″ x 4″.

Separate Front and Back Labels.

The main disadvantage of separate front and back labels is that you get less space on which to put your information, In this example, you’d have 8 square inches each, front and back. And, of course, you have the cost of 2 labels compared to one. Even though the label size is smaller and there’s one more per sheet, the cost of 2 is still more than the cost of one larger label.

The biggest advantage is that you might be able to use the same back label for all your different scents of lotions (assuming the only difference is your choice of fragrance… which can just be listed as “fragrance” in the ingredient declaration). In the long run, that might save some money because you could purchase a larger quantity.

Single Wrap-Around Label

The advantage of a single wrap-around label is that you get more label “real estate” – in this case, 24 square inches. Compared to a front and back label, you’d have an extra 8 square inches in the single label that you can use for additional marketing information. And, generally, the price of one label is less than the cost of two of the smaller ones.

The disadvantages are that, first, they are difficult to apply by hand and achieve an absolutely straight line. If they aren’t straight, then the back doesn’t align, and it can appear unprofessional. And, second, if you change anything, you have to re-design and print a completely new label. If you have several similar items, each one needs its own design and label.

Matching the Size to the Stock

Finally, there’s the matter of matching the size to the stock you want. If you’ve chosen an unusual stock (such as gold or silver foil or a waterproof polyester) you may have fewer size selections available than a basic white matte or glossy paper stock.

Adhesive

There are many, many, many different adhesives in the world, but unfortunately when it comes to stock labels the choices are pretty limited … permanent and removable.

For the most part, permanent adhesive is the best option for soap and cosmetic labels. It’s on there and no matter where the product ends up, the label isn’t likely to come off. That said, test the product to determine what does, in fact, remove the permanent adhesive.

If you’ve ever tried to remove the label from a bottle or jar, you know that sometimes it’s water that will get it to come off. Sometimes it’s soap. Or oil, Or Goo-Gone. Or an essential oil (orange essential oil breaks down lots of different adhesives).

If your product is going to be used in the shower, then you definitely don’t want an adhesive that is removed with water. If the product is an alcohol-based perfume or room spray, you wouldn’t want a label that would come off with alcohol. The same is true for an oil-based product or one with a high concentration of essential oils or fragrance oils.

Removable labels are good if you are using a biodegradable package of some kind, which must have the label removed in order to be processed. Or if you are providing containers that could be repurposed if the label were removed.

Removeable labels are also good if you find often yourself in the unfortunate situation of having to re-label or re-use containers for some reason. If they have a permanent label, you would probably just have to toss them and live with the cost of the loss.

Availabilty, Quantity, and Price

In the final analysis, it comes down to what’s works for you AND is available within your quantity and price range.

You may want gold labels 4 x 6 labels, for your cosmo bottle, but that could run you as much as 70¢ per label (before the cost of ink and any waste). That’s a significant bump in the cost per product. If you’re creating a luxury product at a $49.95 price point, that might be acceptable. However, if your price point is $7.95, that probably won’t work.

Or perhaps you’re looking for a removable laser polyester label in a unique size that isn’t typically available.

Well, anything can be available if you can pay the price. It might be that in order to get that particular combination it requires getting them specially ordered with a minimum quantity of 5,000 (or even specially manufactured at a minimum quantity of 100,000). At that quantity, they’ll probably be cheaper than all your other options, but if you’ll only use 2,000 of that particular label each year, it would take you 50 years to use up the 100,000 labels. Probably not worth it.

Bottom line, the smaller your quantity, the higher your price and the more you are going to have to select within the typically available stock. As you start working toward higher quantities, you can take advantage of lower prices (or go into more expensive stock to boost your brand look).

One way to cut down the price is to increase your quantity by using the same label size on different products. That can take some ingenuity to make it work, but can sometimes be done.

Testing

Before committing to a hefty investment (whatever that may be for you), try the label on the actual container to make sure it fits and looks okay.

Then test the ink, label and adhesive in all conditions your product might be subjected to, for example:

- In the sunny window of a store display (does the ink color fade?)

- In a freezing plane as its being shipped to a customer (does the adhesive or label crack?)

- In a hot shipping container (does the adhesive melt or slip?)

- In a shower (does the ink smudge or run? adhesive release?)

- Used with wet hands (does the ink smudge or run? adhesive release?)

- Used with oily hands (does the ink smudge or run? adhesive release?)

- Rubbed against other products or packaging containers (does the ink smudge, chip, or crack?)

Final Thoughts

A label that fits well makes your product look thoughtful, finished, and professional. It’s part of your overall customer experience. It should hold up under real-life use, match your brand story, and make your product look as good on the outside as it is on the inside.

Whether you choose matte paper or glossy film, kraft stock or vinyl, your decisions about materials, finishes, and adhesives all add up to a label that does its job—and does it beautifully.

Leave a Reply

You must be logged in to post a comment. Login/Register